Casatella Trevigiana and its Cheesemaking Process

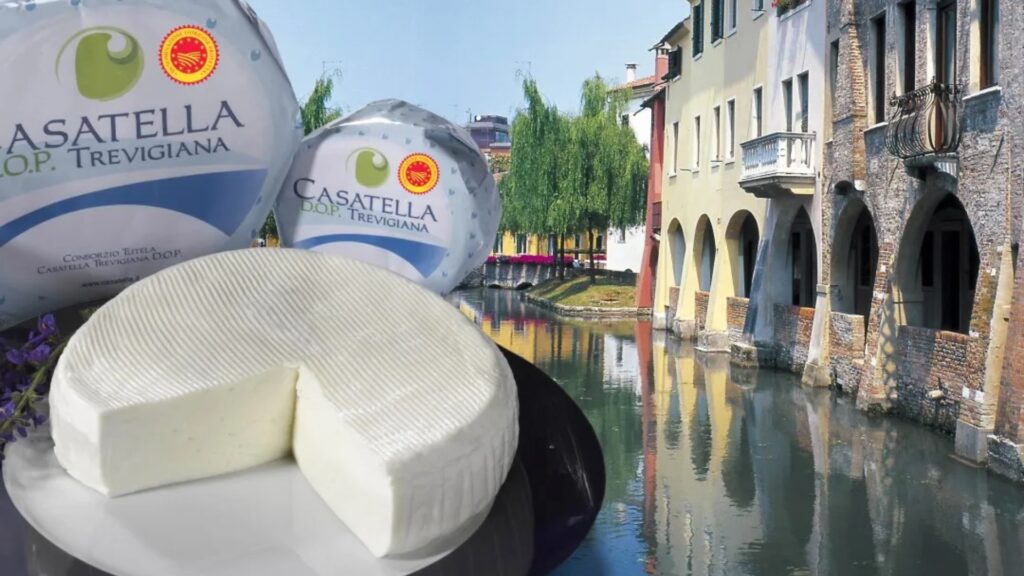

Casatella Trevigiana is a fresh cheese typical of the province of Treviso, entered in the register of protected designations of origin (PDO) in 2008.

Its uniqueness derives not only from the raw materials used but also from the rigorous cheesemaking process that respects ancient local traditions and specific processing techniques.

This article explores the fundamental steps in the production of Casatella Trevigiana and provides a historical background to better understand this prized cheese.

Historical Notes

The origins of Casatella Trevigiana date back centuries, when the farmers of the Marca Trevigiana produced this cheese for family consumption. The name ‘Casatella’ probably derives from ‘casa’, indicating the domestic and homemade nature of its production. Over the course of time, Casatella has gained more and more recognition, becoming a symbol of Treviso’s cheese-making tradition. The PDO registration in 2008 consolidated its reputation and guaranteed the protection of its name at European level.

The Cheesemaking Process

The production process of Casatella Trevigiana must begin no later than forty-eight hours after milking to ensure the freshness and quality of the milk

1

Pasteurisation

Milk is pasteurised at a temperature of between 70 and 75°C for between 15 and 25 seconds. This step is essential to eliminate any pathogens without compromising the organoleptic characteristics of the milk.

2

Heating

After pasteurisation, the milk is heated to the coagulation temperature, which varies between 34 and 40°C, depending on the season and the acidity of the milk.

3

Acidification

Acidification is achieved by adding lactic acid from the production area. This step is crucial as acidity affects the final texture of the cheese, which must be firm and not spreadable. The local microbial flora plays an essential role, giving the cheese its unique flavour and aroma characteristics. Milk starter is prepared by heating the milk to 65-68°C, cooling it to room temperature and allowing it to ripen to an acidity of 8-12 SH/50 ml. The quantities used can vary between 1% and 5% of the milk mass.

4

Coagulation

The milk is coagulated by adding bovine rennet, liquid or powder. The coagulation time must be between 15 and 40 minutes.

5

Curd Breaking and Resting

The curd is cut crosswise carefully so as not to crumble the mass and left to rest for 45-50 minutes, a longer time than for typical fresh cheeses such as cream cheese.

6

Stirring, Curd Extraction and Filling

The curd is stirred slowly to begin the draining process and then extracted and formed into cylindrical moulds with perforated walls. The duration of this phase varies between 7 and 13 minutes.

7

Salting

Salting takes place in a salt solution at 16-20° Baumé, with temperatures between 4 and 12°C. The salting time varies according to the size of the wheels: 40-50 minutes for small wheels and 80-120 minutes for large ones.

8

Maturation

The cheeses are placed in the ripening room at a temperature of between 2 and 8°C for a period of 4 to 8 days. During this period, the cheeses are turned at least every two days.

9

Packaging

Finally, Casatella Trevigiana is packaged and placed on the market.

Casatella Trevigiana is a cheese that embodies the tradition and quality of artisan cheese-making in the Marca Trevigiana. Respect for the production phases and attention to the local microbial flora guarantee a unique product, capable of delighting the most demanding palates and keeping alive the link with the historical roots of the territory.

DON'T FORGET TO FOLLOW US ON OUR SOCIAL NETWORKS!

Every week we offer posts and articles on the food industry to keep you up-to-date and in step with the changing market!