Destemming Machines: Function, History, Utility and Advantages in Wine Production

Function of Destemming Machines

Destemming machines are devices used in the wine industry to separate the stems from the grapes. This process is essential in winemaking, as the stems can negatively affect the flavour of the wine by introducing unwanted tannins and other substances that can compromise the final quality of the product.

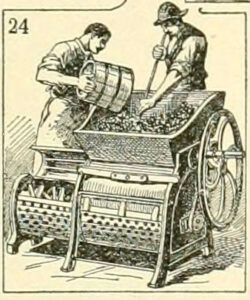

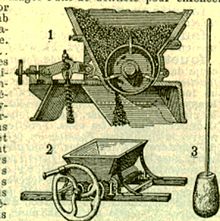

The destemming process involves the grape bunches being fed into the machine, where a rotating drum with holes separates the berries from the stems. The berries are then transferred to the crushing process, where they are crushed to release the must, which will be fermented to produce wine.

History and Discovery of Destemming Machines

The history of destemming machines dates back to the 19th century, when mechanisation of wine-making began to develop to increase efficiency and improve wine quality. Prior to this innovation, the destemming and crushing of grapes were manual processes, performed with simple tools such as sticks or by hand, requiring significant amounts of labour and time.

The first patent for a destemming machine was filed in France in 1843 by Joseph-Gaspard Jarry, whose device represented a remarkable technological advance for the time. Over time, destemming machines evolved, becoming increasingly sophisticated and automated, incorporating advanced technologies to improve the efficiency of the process.

Usefulness of Destemming Machines

Destemming machines play a crucial role in wine production for several reasons:

- Efficiency: They automate the destemming and crushing process, allowing large quantities of grapes to be handled in less time than with manual methods.

- Product Quality: They allow more precise separation of the stems from the grapes, improving the quality of the must and the final wine.

- Labour Reduction: Decrease the need for intensive manual labour, reducing operating costs.

- Consistency: They ensure homogenous crushing, which is essential for uniform fermentation and consistent wine quality.

Benefits for Production

The adoption of destemming machines brings several benefits to wine production:

- Increased Productivity: Thanks to speed and precision, wineries can increase their production capacity, responding better to market demand.

- Improved Wine Quality: Careful removal of stalks prevents contamination of the must with unwanted tannins, preserving the grape’s natural flavours and aromas.

- Economic Savings: By reducing labour costs and increasing the efficiency of the production process, wineries can optimise their investments.

- Innovation and Sustainability: Modern destemming machines are often designed to be more sustainable, with lower energy consumption and better waste management.

In conclusion, destemming machines are a key component of the modern wine industry. Their evolution has enabled wineries to improve the quality and efficiency of production, helping to make wine more accessible and globally appreciated. The combination of advanced technology and attention to quality has transformed a traditional process into a modern art, capable of meeting the needs of today’s producers and consumers.

DON'T FORGET TO FOLLOW US ON OUR SOCIAL NETWORKS!

Every week we offer posts and articles on the food industry to keep you up-to-date and in step with the changing market!