Revolutionary rotary tangential filter: doubled yields and halved costs! From lees to bottle! Up to 95% filtrate recovery.

- It is the first dynamic rotary tangential wine filter equipped with the innovative back-wash system.

- It represents the most viable alternative to vacuum filtration and filter press in must and wine sediment filtration without adjuvants.

- The principle used is tangential filtration applied to discs rotating at high tangential speed. This avoids clogging and allows easy self-cleaning of the membranes.

- High quality level of the filtrate which, in the case of wine, can be bottled directly as with a traditional tangential.

- No reduction in red color (Abs at 520nm).

- No oxygen absorption (with limited nitrogen injection).

- High nominal yields (25 to 100l l/m2/h with lees).

- Long filtration cycles(up to 96 hours non-stop).

- Low energy consumption process when compared to traditional tangential filtration systems.

- Maximum versatility to filter not only lees but also wine, juices and sugar syrups with superior results compared to all tangential tubulars.

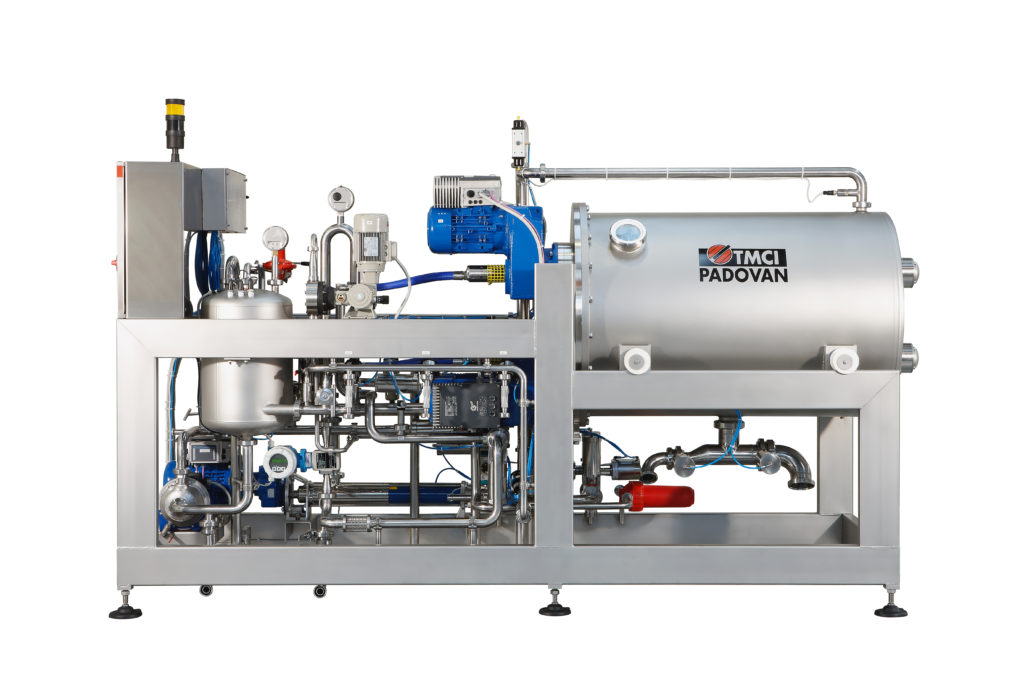

- Models available from 1m2 to 20m2 and multiples, compact and easy to use.