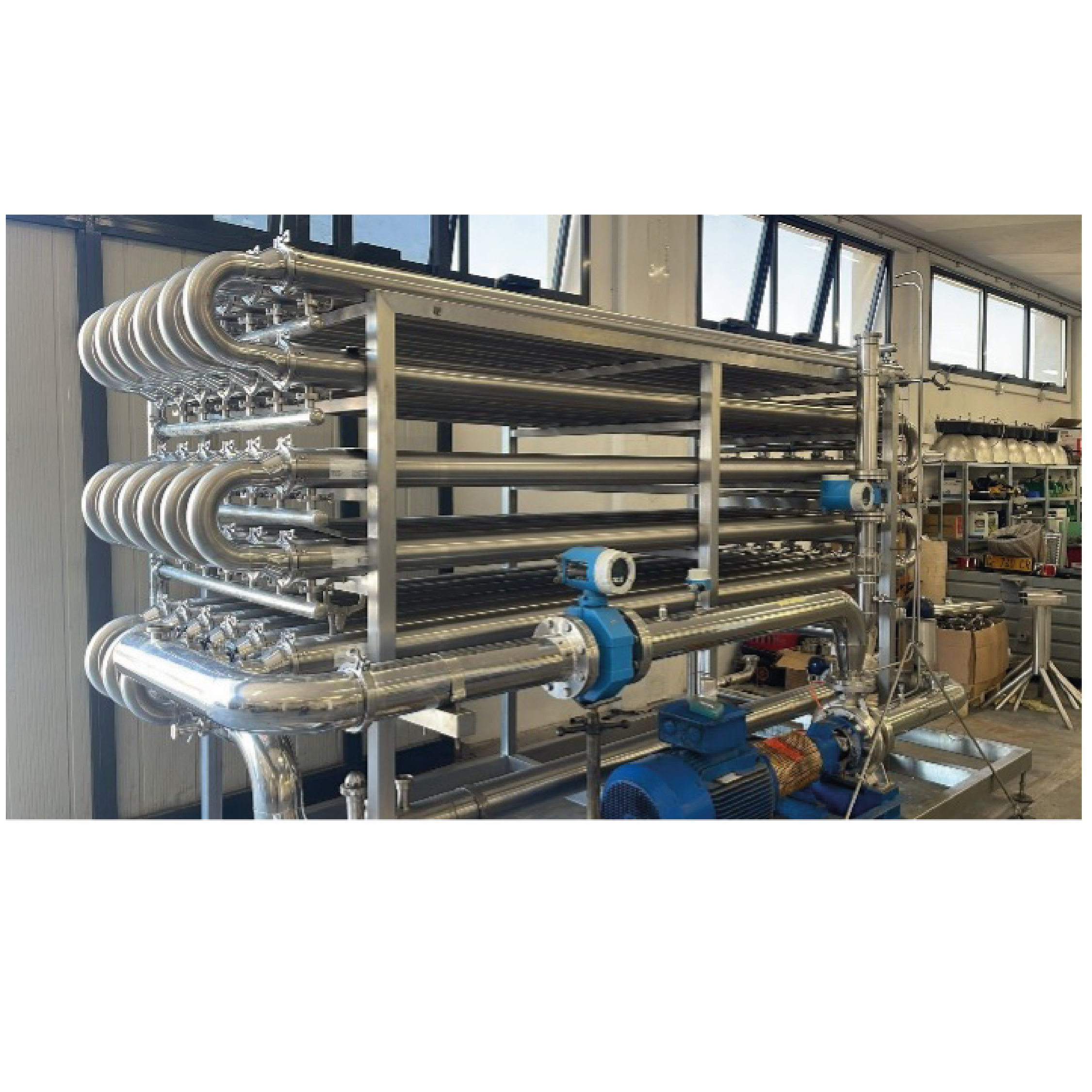

ULTRAFILTRATION SYSTEM

COMPANY: ZANLORENZI

PRODUCT TO BE MADE

Grape juice

In this machine, two used machines were purchased and the membranes were replaced with new ones; changes were made to the assembly of the membranes as they had different sizes and the centre distance of the membranes was changed.

Maintenance was carried out on the pumps, bringing them to a working frequency of 60Hz, as the machine would operate at this frequency, and in the case of the pumps, the rotating parts were rotated so that they would operate correctly at this frequency.

All bearings and seals of valves, pumps and pipes were changed, damaged instruments were replaced and valves reconditioned, new pipes were made due to a bad fit of the previous ones, manifold terminals were changed and the electrical system was completely renewed.

BEFORE

DURING