The juice clarification process: a detailed guide

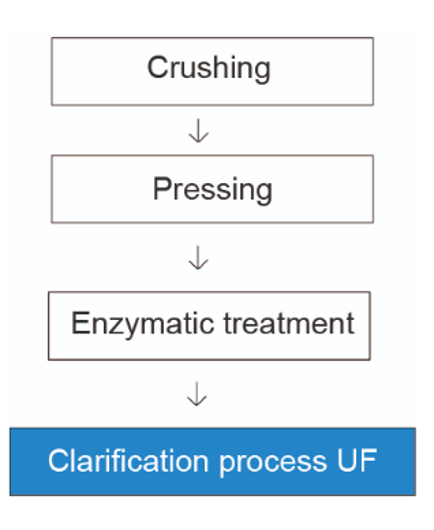

The production of fruit juices follows a complex process, consisting mainly of four basic stages: crushing, pressing, enzymatic treatment and clarification/filtering through membranes, each of which comprises a series of crucial cycles

During the crushing and pressing of the fruit

Pectins and starches require specific enzymatic treatment to remove them before microfiltration/ultrafiltration.

Depectinisation, which is essential for effective filtration as it reduces the viscosity of the juice

It is achieved through the use of enzymes.

This process is of considerable importance, along with the type of activated carbon or bentonite added, if any, as it directly influences the membranes’ ability to filter optimally.

The most advanced method of juice filtration is the use of microfiltration (MF) or ultrafiltration (UF) membranes.

These membranes, used in batch or modified batch mode with depectinised juice, are designed to maintain typical juice characteristics such as sugar content and natural pH. In addition, the diafiltration step is commonly used to optimise the yield by recovering the sugar fraction from the final concentrate, which is then eventually destined for animal husbandry.

Integrating these juice clarification processes into the production process ....

It ensures the production of high-quality juices that retain the flavour and nutritional properties of the raw material used.