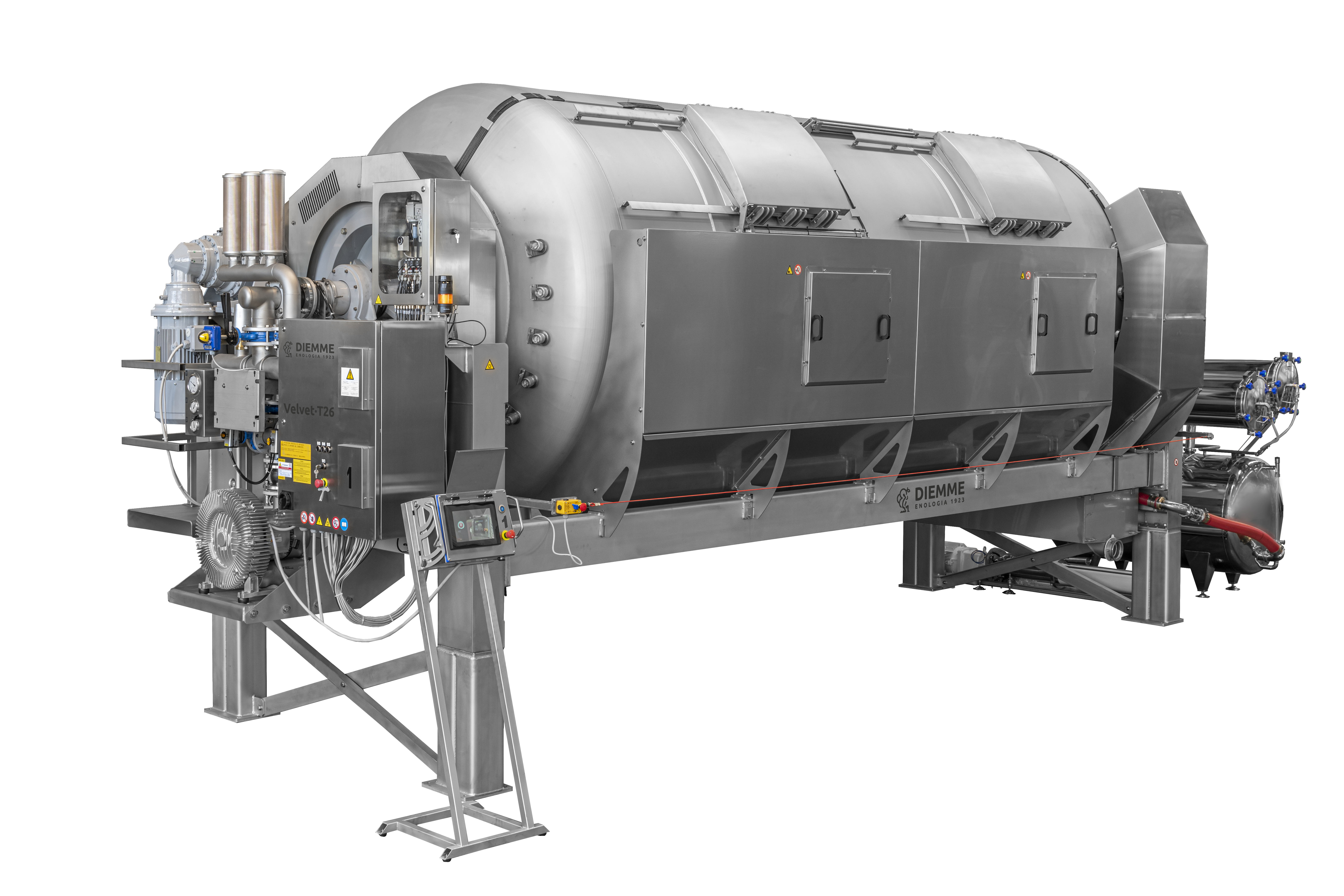

- Tank: AISI 304 stainless steel closed tank certifi ed 97/23/EC (PED). Mirror-polished channels (A), self-cleaning with high drainage capacity (B). Thanks to the special design of the channel and membrane, even minimal quantities of product can be pressed, without quantity limits (C).

- Automatic, water-tight gate valve: Large door moved by a pneumatic jack, the opening of which can be full or partial. Watertight with pneumatic seal placed on the tank. Optional two product loading hatches with the possibility of independent opening

- Membrane mounting system: Limits stresses by extending the service life of the membrane. Allows rapid assembly and disassembly.

- Pressing membrane: Consists of plastic material suitable for food contact. There are no minimum limits of product to be pressed.

- Pneumatic circuit: Optimized and easily accessible pneumatic circuit, increased blower installation possibility to reduce up to 30% downtime.

- Safety valve: Allows for safe maintenance operations on the diaphragm.

- Belt drive: Reduces mechanical stresses on transmission components and improves system reliability.

- Operator panel: Panel mounted on a stand that allows its tilt adjustment. Easily removable from the machine to protect it during periods of prolonged inactivity.

- Rocking function: Allows the load to be equalized by rocking the tank.

- E-panel operator interface: E-panel operator interface is simple and intuitive with a large TouchScreen. There are 32 pressing programs suitable for all types of grapes and fully customizable. Download and upload of programs with USB flash drive.

- Intelligent program FIP: Automatic pressing program that optimizes cycle time based on the flow rate of must leaving the press. The system includes the flow meter with which the amount of must per cycle can be calculated.Pulse Jet

- Automatic washing system: Uses high-pressure water and air for deep cleaning of channels and tank.

- Maceration device: Allows pellicular or carbonic maceration operations to be carried out on grapes inside the press tank.

- Intelligent MIP program: Automatic pressing program that optimizes cycle time based on grape volume reduction.

- Load Cells: Load cells for continuous monitoring of the mass of product being processed.

- Double Drain: Increases drainage capacity during filling and the early stages of pressing while maintaining the effi ciency of the washing device.

- Motorized Wheels: Automatic device for moving pneumatic presses in the winery.