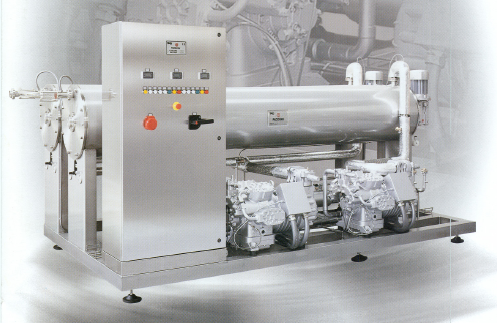

Scraped surface evaporators (FRIGOUNIVERSAL)

Scraped surface evaporators consisting of:

- One or more stainless steel evaporators where the liquid, with continuous passage, transfers heat directly to the refrigerant;

- Hermetic, semi-hermetic or open type compressor;

- Condenser designed for cooling with water or air;

- Control and safety valves and instrumentation, electrical cabinet.

Each tubular element has the surface in contact with the liquid to be cooled continuously scraped by rotating vanes; on the other surface, evaporation of the refrigerant takes place.

The liquid to be cooled flows continuously within the chambers bounded by the tubular elements and two end caps, one of which supports the geared motor for rotation.

Each module is thermally insulated by a layer of polyurethane.

As a result of the scraped surface, a high heat exchange efficiency and uniform refrigeration is achieved even with very viscous liquids.

Dry expansion evaporators

Freon is normally used as the refrigerant.

Flood type evaporators

Ammonia is normally used as the refrigerant.