Receiving, sorting, destemming plants.

A complete range of technological solutions for receiving, destemming, sorting and transporting fermented grapes and pomace. Design, fabrication, automation and installation of complete plants.

Auger receiving tanks

Receiving tanks are an essential element in the receiving stage and the start of grape processing. All models are made with a solid tubular frame and entirely of AISI 304 stainless steel to ensure the best quality and durability. Hoppers are produced with capacities from 3 to 45 t and can be equipped with one or two unloading augers, depending on the required capacity, and other different options. Customized models can be produced according to the space and specific needs of each winery.

Vibrating receiving tanks

Vibrating receiving tanks are made entirely of AISI 304 steel, designed specifically for receiving hand-picked grapes in crates and/or bins. This system uses vibration to distribute the grapes and convey them to sorting belts or destemming systems, etc. This machinery can be equipped with wheels, a draining section, and has an electrical panel with Inverter that allows for flow rate adjustment. The vibrating tanks have a capacity ranging from 0.5 to 5 t.

Kappa destemmers

- High-tech de-stemming and crushing machines from 5 to 150 ton/h designed for processing whole or mechanically harvested grapes.

- De-stemming cage with particularly fine finish and double thickness to ensure the integrity of the berries and avoid lacerations. Wide choice of hole diameter.

- High-strength beater shaft with handles adjustable in height and orientation to meet all processing requirements. Available in stainless steel or rubber-coated on request.

- Draining hopper to regularize feeding by increasing productivity and quality of de-stemmed product. Special hoppers and bypasses are available upon request.

- Machine control via remote panel with rotation speed adjustment via Inverter. From the Kappa 50 model upwards, a second Inverter can be mounted to adjust beater speed and cage speed independently.

- Easy access to every part to facilitate maintenance and cleaning operations. External greasing points and built-in wash bar.

Open Grape Crushing Unit.

Innovative crushing system with cylindrical rollers covered in food-grade rubber with a shape designed to allow the berry to open. In white winemaking it improves pressing performance, in red winemaking it increases color intensity in a short period of time and increases polyphenolic assets.

Useful data

The data given are for indicative purposes only and may vary depending on the degree of ripeness, the type of grape and depending on how it is filled. All data refer to initial whole grapes, before any operation such as destemming, crushing, maceration, fermentation, etc.

Kappa Selection

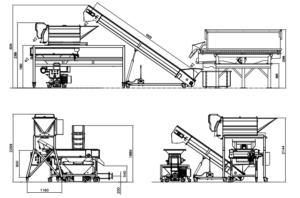

Kappa Selection lines are created by combining established technologies with practical winery experience. Merging them into an integrated system allows for the enhancement of individual equipment versatility and production flexibility. The Kappa Selections are in order composed of a destemming system, a roller selection table, a crushing unit, and a pump to evacuate the processed product. Several processing modes are possible due to the extraction movement: – de-stemming; – de-stemming and selection; – de-stemming and crushing; – de-stemming, crushing and selection; A single electrical panel built into the structure controls each machine. In addition, the system can be integrated with tanks, receiving hoppers, vibrating sorting tables, sorting belts and elevators to transport the product. We make Kappa Selection lines from model 15 up to model 90. The Kappa Selection 15 is also designed in the stand-alone version and in this case all equipment retains its structure, can be useful where the winery also uses the machines for other purposes.

Layout Kappa Selection